I became interested in Magnetic Spin Toys after hearing Chris Danforth from the University of Vermont talk about chaotic systems. His discussion and demonstration of the unpredictability of a double pendulum made me wonder what it would be like to explore systems with large numbers of magnetic spin toys, like those mentioned at the top of this page. I tried to purchase some from Amazon and eBay, but they are no longer available, so I decided to manufacture some and play with them. I searched for and found the patent for the original toy, which you can find here.

The original design employs a complex injection molded plastic part that was beyond my capabilities. I considered attempting a 3D design for the part, and fabricating it at the Vermont FabLab with a 3D printer, but decided to go low tech at first.

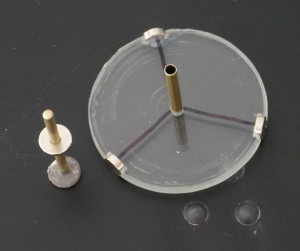

I purchased a hole saw and used that to cut disks out of a sheet of 1/4 inch plastic. I glued magnets to the circumference of the disks and pressed a brass tube through the center of the disks for horizontal stabilization. I epoxied a brass rod to a ring magnet and dropped a similar ring magnet onto the rod, oriented so that the two magnets would repel. I then dropped the plastic disks onto the rods, so that the opposing magnets would serve as a magnetic bearing, as discussed in the patent.

This picture shows the component parts of an individual magnetic spin toy. The brass rod is shown in the lower left. It is epoxied to the ring magnet at the bottom of the rod; the magnet in the middle of the rod is held suspended by the opposing magnetic force. The plastic disk is on the right, with the three magnets and the brass tube:

When assembled, they look like this:

I use a steel sheet (actually, a spare music stand) as a base for the magnetic spin toys. This allows me to reposition them quickly and easily.

You can see videos of all of this as follows:

Assembly of components and demonstration of magnetic bearing and spinning

Two magnetic spin toys interacting

Three magnetic spin toys interacting

Four magnetic spin toys interacting

Four magnetic spin toys interacting in a square array

Four magnetic spin toys interacting in a rhomboidal array

Demonstration of magnetic interaction with distant magnetic spin toys

You might find it interesting to download the videos (I use DownloadHelper in FireFox) and step through the videos one frame at a time (I use KMPlayer) to watch how the disks respond to each other. I will probably color code the magnets for future videos.

My original thought was to create an array of interacting spinners, one of which could be driven by a hidden microprocessor-controlled motor. The microprocessor would be set up to drive the motor in varying patterns to ensure that the array never stopped. I considered linear or curved lines of spinners, perhaps attached to loops. It turns out that arranging the spinners in tightly packed arrays also works well. The patent demonstrates that the axes of the spinners do not need to be parallel: you can arrange for the spinners to be at angles to each other, so it would be possible to arrange them on the surface of a hemisphere. My use of a steel surface for testing could be expanded into using a curved surface for the “final” system. So. Lots of things to explore.